How to choose the best fixture

that will last forever

To improve the thermal-acoustic insulation level and the security of your fixture, you can use other types of glass, including double or triple glazing, in laminated glass, as recommended by the current product standard UNI 7697:2014, in turn with low emissivity treatment, with selective or reflective layer.

In choosing the glass, be aware that the best performance is achieved through the right balance between the thickness of the sheets, the coupling of several sheets with a thin film able to absorb the acoustic vibrations, when appropriately treated, and gaps filled with specific inert gases that improve the thermal capacity.

The method of connecting the various sheets that form the double/triple glazing is also a very important aspect to be taken into consideration, since special materials of the latest generation are able to reduce heat loss by 50% in the area of the fixture, eliminating the problem of surface condensation.

Safety glass

Tempered glass is able to resist mechanical stresses and temperature ranges much higher than normal float glass, thanks to the special heat treatment and sudden cooling to which they are subject. In the case of very violent, accidental shocks that cause breakage, they shatter without causing hazards, collapsing into tiny fragments.

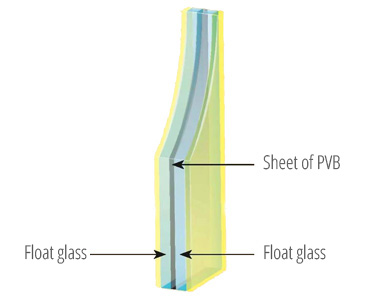

Laminated glass, on the other hand, is composed of several layers of glass, between which a thin layer of plastic, transparent and invisible film is inserted that not only makes the glass particularly resistant but holds the fragments in the case of breakage, avoiding it shattering and making the glass even safer for children.

Thermal control glass

Reflecting glass has a surface coating that enables it to reflect the light of the sun and keep out excess heat, while maintaining a high level of brightness in the interior environment, although not fully transparent. This feature that makes it one of the most popular choices for large exposed glass surfaces, to which it is still possible to give an aesthetic and architectural touch.

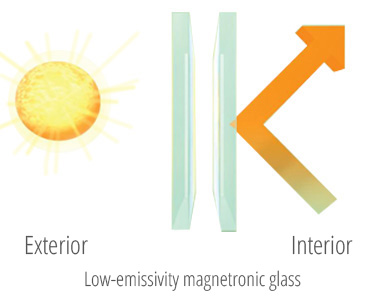

Low-emissivity glass is made from one or two sheets of glass able to contain heat loss, thanks to a layer of metal oxide deposited under vacuum on the inner/outer sheet. It is particular suitable for regions with cold climates due to its capacity for thermal retention, since, once heated, it enables the benefit of the heat from the sun's rays to be available in the winter months.

Finally, selective glass is able to “select” the various wavelengths that form the light and reflect those wavelengths that “transport” heat while allowing those that "transport" light inside the building. This occurs thanks to a deposit of metal oxide on the external sheet. This is a very sought-after function in warmer climatic regions to keep away the great heat of summer, where a very high level of light is nevertheless required, since it appears to be completely transparent.

Acoustic insulation glass

Sound-absorbent glass has high insulating power from the acoustic point of view, obtained through the use of elastic glasses, joined together and coated with soundproof film. This is recommended for very noisy areas, such as industrial zones or near roads with heavy traffic.

An important factor in assessing an “acoustic” glass is also the various thicknesses of the individual sheets, given that every thickness (3, 4, 5 or 6) "splits” a specific sound frequency, so several thickness mean less sound is perceived inside the building.